Our breakthrough

technology

Sakowin’s patented hydrogen production solution:

- Cost competitive

- Energy efficient (5 times less energy than an electrolyzer)

- Negative or neutral in CO2 emissions

- No use of water

Sakowin’s Unit provides

Plasmalysis based Hydrogen

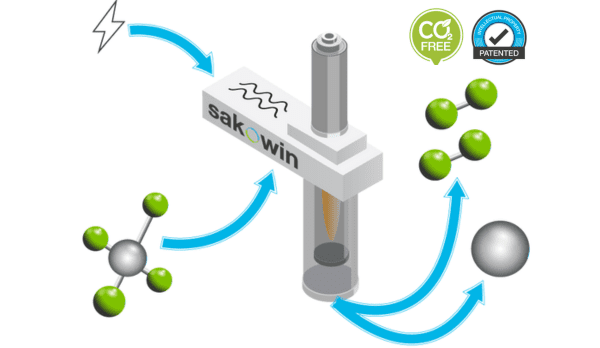

We have developed and patented an innovative proprietary low energy

and CO2-free (bio)methane decomposition process, based upon Plasmalysis.

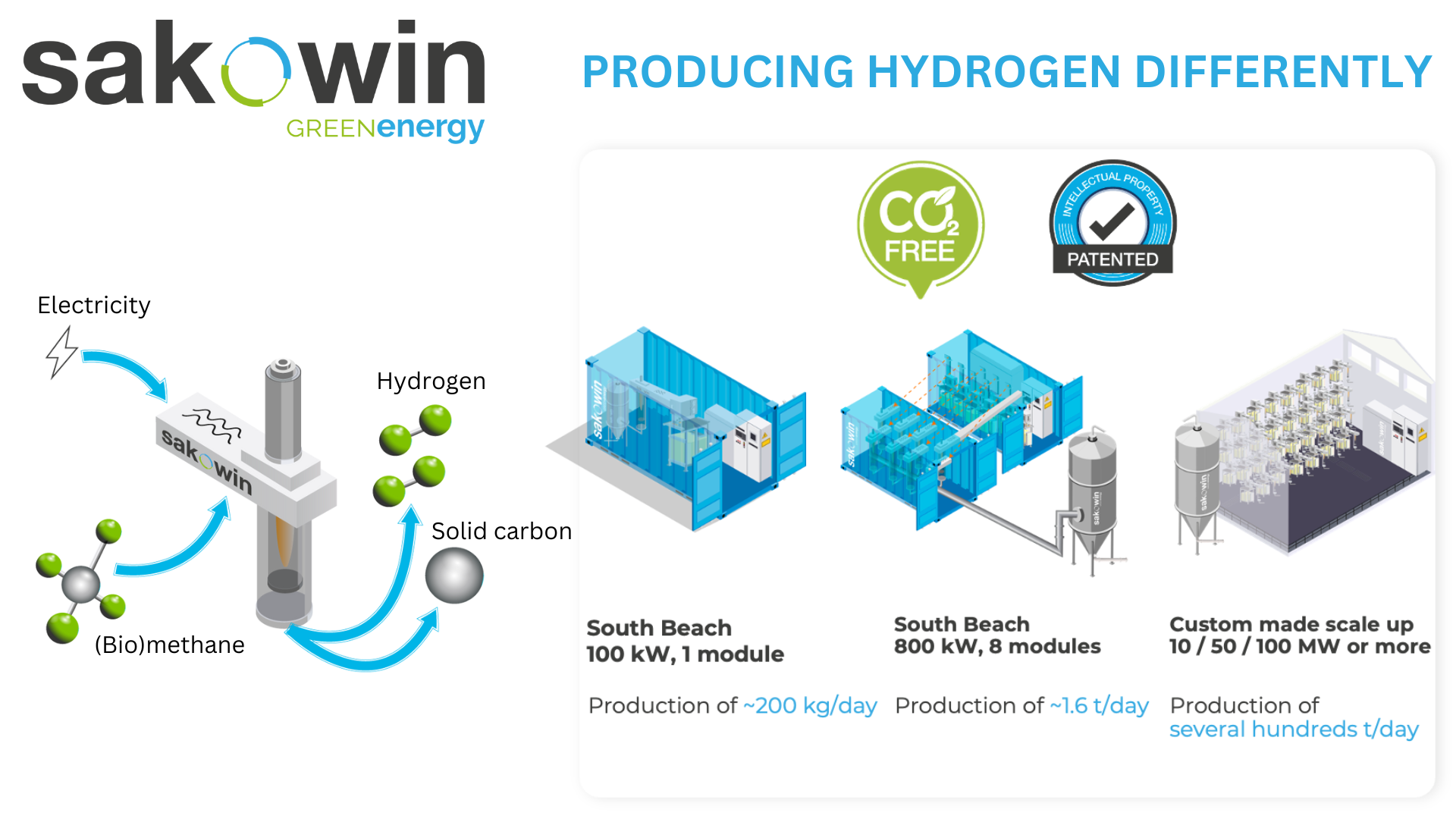

Our priorities has been to build a compact, modular, stackable and on-site unit:

- Compact – Optimized integration in your installations.

- On-demand – The use of microwave plasma allows you to produce when you want, adapting to the needs of a variety of industries and sectors.

- Stackable – The reactors can be added together to produce useful quantities and thus adapt to entities from 200 kg H2 per day, up to the needs of major industrialists in the oil and gas sector, severals hundred tons of hydrogen per day.

- On-site – The unit comes at the end of the gaz infrastructure, suppressing the need to build a dedicated hydrogene infrastructure one from scratch. In short, it unlocks a massive adoption from every industries and sectors.

Sakowin’s technology and product are protected by 3 patents, filed and pending, relating hydrogen production integrating a microwave plasma technology. The patents cover the production, distribution and scaling of a technology to produce sustainable hydrogen.

The energy transition rests on three pillars, all of which are essential to its success: process energy efficiency, the energy circular economy, and sustainability from both an environmental and economic perspective.

ENERGY EFFICIENCY

it is essential to aim for energy efficiency in processes and to take into account the entire life cycle of each energy source used.

CIRCULARITY

we need to move from global to local and promote technologies to recover waste and co-products.

SUSTAINABILITY

we need sustainable energy systems from both an environmental and economic point of view.

The process of producing black, brown and grey hydrogen produces CO2.

Blue hydrogen is a similar process combined with CO2 capture and storage to reduce emissions.

Green hydrogen is produced by water electrolysis.

Turquoise hydrogen produced by (bio)methane plasmalysis uses both electricity and CH4, but with up to 5 times less electricity than water electrolysis.

Hydrogen is a solution to face these critical energy challenges

Hydrogen is light, storable, energy-dense, and produces no direct emissions of pollutants or greenhouse gases. As a clean energy vector, it will play a key role in decarbonizing industries and sectors where other alternatives might be unfeasible, including, long-haul transport, power generation, buildings, massive industrial projects, chemicals, iron and steel – where it is proven difficult to meaningfully reduce emissions.

Want to discuss about our tech?

Feel free to reach out in the most convenient way